Choosing the right glass material for lamp shades is one of the most critical decisions in lighting product design and manufacturing. The glass you select directly affects heat resistance, safety, light diffusion, durability, compliance, cost, and long-term performance.

For lighting manufacturers, interior designers, architects, and hospitality project buyers, understanding the differences between tempered glass, borosilicate glass, and soda-lime glass is essential to avoid cracking, quality failures, and costly project delays.

In this guide, we break down each material from both a technical and commercial perspective, helping you make the right choice based on application, environment, and production scale—while avoiding common mistakes that B2B buyers often encounter.

Lamp shades are not purely decorative components. In real-world use, they must withstand:

Continuous heat exposure from bulbs or LED modules

Thermal shock from switching lights on and off

Mechanical stress during installation and transportation

Long-term exposure to UV light and ambient temperature changes

Selecting the wrong glass material can result in:

Cracking or shattering during use

Uneven light diffusion and glare

High breakage rates during shipping

Non-compliance with safety or project standards

That is why professional lighting manufacturers evaluate glass materials not only by appearance, but by thermal performance, mechanical strength, and consistency in mass production.

Soda-lime glass is the most common type of glass used worldwide. It is composed mainly of silica (SiO₂), sodium oxide, and calcium oxide. Because it is easy to melt and shape, it is widely used in household glassware, decorative products, and standard lamp shades.

Maximum working temperature: ~150–200°C

Low resistance to thermal shock

High clarity and smooth surface finish

Easy to cut, drill, frost, or decorate

Lowest raw material and production cost

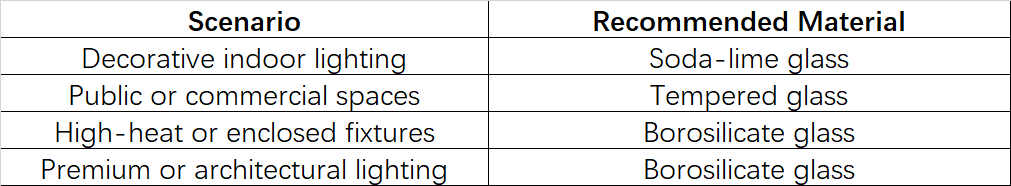

Soda-lime glass is ideal for:

Decorative table lamps and wall sconces

Low-heat LED lighting fixtures

Indoor residential lighting

Projects with strict cost targets

Its excellent workability allows for:

Complex shapes

Thin or thick wall designs

Frosted, etched, painted, or sprayed finishes

This makes it a popular choice for custom decorative lamp shades where aesthetics matter more than extreme performance.

The biggest drawback of soda-lime glass is its poor thermal shock resistance. Rapid temperature changes—such as turning a lamp on after it has cooled—can cause cracking.

It is not recommended for:

High-wattage bulbs

Enclosed fixtures with poor ventilation

Outdoor or commercial environments

Tempered glass is soda-lime glass that has undergone a controlled heat-treatment process. This process increases surface compression, making the glass significantly stronger than untreated soda-lime glass.

3–5 times stronger than regular glass

Better resistance to mechanical impact

Breaks into small, blunt granules (safety glass)

Moderate heat resistance

Tempered glass is commonly used when safety and durability are top priorities.

Typical applications include:

Commercial lighting fixtures

Hospitality and public spaces

Pendant lights in high-traffic areas

Fixtures requiring compliance with safety regulations

Because of its strength, tempered glass reduces:

Breakage during installation

Damage during shipping

Safety risks in public environments

One key limitation of tempered glass is post-processing restriction.

Once glass is tempered:

It cannot be cut or drilled

Shape and holes must be finalized before tempering

This means:

Design changes after sampling are costly

Complex customization requires careful upfront engineering

For B2B buyers, this makes supplier engineering support especially important.

Borosilicate glass contains boron oxide, which significantly improves thermal and chemical resistance. It is commonly used in laboratory glassware, cookware, and high-performance lighting applications.

Maximum working temperature: 300–500°C

Excellent thermal shock resistance

Low thermal expansion coefficient

High chemical stability

Borosilicate glass is the preferred choice for:

High-temperature lighting fixtures

Enclosed lamp designs

Industrial or architectural lighting

Premium or long-life products

It performs exceptionally well in environments where:

Lamps are frequently switched on/off

Heat buildup is unavoidable

Long-term stability is required

From a brand perspective, using borosilicate glass can significantly reduce:

Warranty claims

Cracking complaints

Project replacement costs

Borosilicate glass is more expensive due to:

Higher raw material costs

Higher melting temperature

More demanding production control

However, for professional lighting projects, total lifecycle cost is often lower due to reduced failure rates.

Glass material also influences how light behaves.

Clear soda-lime glass offers high transparency but can create glare

Frosted or opal soda-lime glass provides softer diffusion

Borosilicate glass maintains stable optical performance even at high temperatures

Tempered glass maintains clarity but limits post-processing finishes

For lighting designers, the ideal solution often combines:

Correct material selection

Surface treatment (frosted, sandblasted, opal)

Proper wall thickness

A professional manufacturer should be able to recommend the optimal combination based on light source and application.

For B2B buyers, compliance is often non-negotiable.

Different markets may require:

Safety glass for public spaces

Heat resistance documentation

Material composition reports

Tempered glass is often specified for:

Commercial projects

Hospitality and public buildings

Borosilicate glass is favored where:

High-temperature safety is critical

Long-term reliability is required

Choosing the right supplier means ensuring they can provide:

Material test reports

Batch consistency documentation

Compliance support for different markets

A common mistake in lamp shade sourcing is focusing only on unit price.

A better approach is to evaluate:

Failure risk

Replacement cost

Brand reputation impact

Long-term maintenance

Choosing the right material is only part of the equation. A reliable glass lamp shade manufacturer should also provide:

Engineering consultation during design

Material comparison and testing support

Prototyping and sampling

Quality control and batch consistency

Secure packaging and export logistics

For B2B buyers, this technical support often makes the difference between a smooth project and a costly failure.

Yes, for low-heat LED applications, soda-lime glass is commonly used.

Not necessarily. It is better for heat resistance, but may be unnecessary for decorative or low-temperature applications.

No. Tempered glass is stronger mechanically, but borosilicate glass has superior thermal resistance.

Soda-lime and borosilicate glass offer the greatest customization flexibility.

Our process ensures quality before mass production

Design confirmation with customer

In-house mold development at our facility

Sample production for approval

Customer testing and feedback

Mass production only after final sample approval

We offer comprehensive custom packaging for safe international shipping:

We operate multiple production lines with experienced workers, enabling stable mass production for orders of all sizes. Our facility ensures consistent quality and reliable on-time delivery for both small batches and large-volume orders.

Lead times vary by complexity and quantity:

We export to over 150 countries and regions worldwide, including:

We maintain a comprehensive global distribution network.