Cracked glass lamp shades are one of the most common—and costly—problems in the lighting industry. Whether you are a lighting manufacturer, interior designer, hotel project buyer, or OEM brand, a single cracked lamp shade can lead to project delays, warranty claims, safety risks, and brand damage.

In many cases, cracking is not caused by poor craftsmanship alone, but by a mismatch between glass material, heat exposure, and real-world application conditions.

In this article, we will explain:

The real reasons glass lamp shades crack

The science behind heat resistance and thermal shock

How different glass materials behave under heat

Common design and sourcing mistakes

How to prevent cracking through better material selection and engineering

This guide is written for professional B2B buyers who want to reduce risk, not just unit cost.

Cracking is more than a cosmetic defect. In commercial and hospitality environments, cracked glass can lead to:

Safety hazards for end users

Failed inspections or compliance issues

Costly on-site replacements

Reputational damage for lighting brands

From a manufacturing perspective, cracked lamp shades often result in:

Disputes between buyer and supplier

Increased return rates

Loss of long-term customers

Understanding why cracking happens is the first step toward eliminating it.

Almost all glass lamp shade failures can be traced back to one or both of the following:

Heat stress (continuous high temperature exposure)

Thermal shock (sudden temperature change)

While these terms are often used interchangeably, they describe different physical mechanisms.

Heat stress occurs when a glass lamp shade is exposed to temperatures that exceed its long-term working limit.

This typically happens when:

Bulb wattage is too high

Ventilation is insufficient

The lamp shade is enclosed

Glass thickness is uneven

Over time, continuous heat causes:

Internal stress buildup

Microfractures in the glass structure

Eventual cracking or failure

Many lamp shades do not crack immediately. Instead, they may:

Survive initial testing

Crack weeks or months later

Fail only after repeated use

This delayed failure makes heat stress difficult to diagnose without proper material knowledge.

Thermal shock occurs when different parts of the glass experience rapid temperature changes at different rates.

Common scenarios include:

Turning a lamp on after it has fully cooled

Cold air hitting a hot lamp shade

Cleaning a warm lamp with a cool cloth

Sudden power cycling

Glass expands when heated and contracts when cooled. If this happens unevenly, internal stress exceeds the glass’s tolerance—resulting in cracking.

Lamp shades are uniquely exposed because:

Heat is concentrated near the bulb

Edges and mounting areas remain cooler

Thickness may vary across the design

This creates temperature gradients, which are the primary trigger for thermal shock.

Soda-lime glass is widely used due to its low cost and ease of shaping. However, it has:

High thermal expansion

Low thermal shock resistance

This means it:

Expands quickly when heated

Cannot tolerate sudden temperature changes

Typical failure scenarios:

Decorative lamp shades used with higher-watt bulbs

Enclosed designs with limited airflow

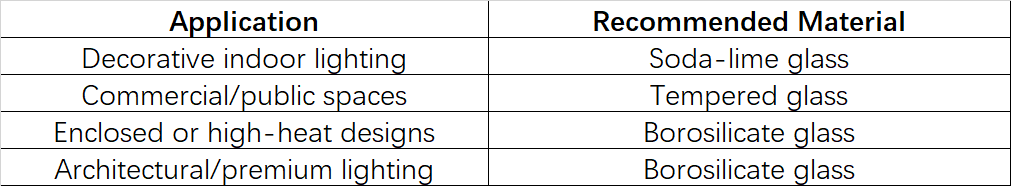

Soda-lime glass is suitable only when:

Heat levels are low

Temperature changes are gradual

Application is strictly controlled

Tempered glass is soda-lime glass that has been heat-treated to improve strength.

Advantages:

Higher mechanical strength

Safer breakage pattern

Limitations:

Only moderate improvement in heat resistance

Still vulnerable to thermal shock

Tempered glass can fail if:

Heat builds up unevenly

Edges are exposed to stress

Design changes are made after tempering

It improves safety, but does not eliminate thermal risk.

Borosilicate glass has a much lower coefficient of thermal expansion, meaning it expands and contracts far less when temperature changes.

Key benefits:

Excellent thermal shock resistance

High working temperature

Stable performance in enclosed designs

This is why borosilicate glass is used in:

Laboratory glassware

High-temperature lighting

Architectural and industrial fixtures

For lamp shades exposed to frequent on/off cycles or high heat, borosilicate glass is the most reliable option.

Even with the right material, poor design can still cause failure.

Inconsistent thickness leads to:

Uneven heating

Stress concentration points

Thicker areas retain heat longer, while thinner areas cool faster—creating internal stress.

Designs with:

Sharp corners

Small holes

Thin mounting areas

are more prone to cracking because stress accumulates at these points.

Fully enclosed designs:

Trap heat

Prevent airflow

Increase internal temperature

Without proper ventilation, even heat-resistant glass can fail.

Glass lamp shade failures are often caused by:

Using incandescent or halogen bulbs

Exceeding recommended wattage

Poor heat dissipation from the light source

Modern LED solutions significantly reduce this risk—but only if properly matched.

Cracking is not always caused by design. Production quality matters.

If glass is not properly annealed:

Internal stress remains locked inside

Cracking may occur later during use

Professional manufacturers use controlled annealing ovens to release internal stress.

Without strict QC:

Thickness variations go unnoticed

Microcracks pass inspection

Batch consistency suffers

These issues often only appear after shipment or installation.

Real-world environments are unpredictable.

Glass lamp shades may be exposed to:

Air conditioning airflow

Open windows in cold climates

Outdoor temperature swings

Cleaning chemicals

Each of these can trigger thermal shock if not considered during material selection.

Maintain consistent wall thickness

Avoid sharp internal corners

Allow for airflow where possible

Match glass size to heat source

Use LED light sources

Control wattage and heat output

Test with real operating conditions

A professional supplier should offer:

Material consultation

Heat resistance testing

Prototyping and validation

Batch consistency control

This engineering support dramatically reduces failure risk.

Before mass production, professional buyers should request:

Heat cycling tests

Thermal shock simulations

Real-use condition testing

Testing under laboratory conditions is not enough—products must be validated in real operating environments.

Choosing glass based on price only

Assuming tempered glass is heat-resistant

Ignoring ventilation in lamp design

Skipping prototype testing

Changing design after material selection

Avoiding these mistakes can save significant long-term costs.

Because cracking is caused by thermal stress, not melting.

Not always. Uneven thickness can actually increase stress.

No, but it has much higher resistance to thermal shock.

Yes, if heat buildup and ventilation are poorly designed.

Glass lamp shade cracking is not random. It is the result of material mismatch, thermal stress, and design oversight.

By understanding:

Heat resistance

Thermal shock behavior

Material properties

Real-world application conditions

B2B buyers can significantly reduce risk and improve product reliability.

Choosing the right glass—and the right manufacturing partner—ensures your lighting products perform safely, consistently, and professionally in the market.