Light diffusion is one of the most overlooked—but most critical—factors in lighting design.

For lighting manufacturers, interior designers, architects, and hospitality project buyers, the choice between clear, frosted, and opal glass directly affects visual comfort, aesthetics, efficiency, and perceived product quality.

A lamp shade that looks perfect on paper can fail in real-world use if the light is too harsh, uneven, or visually uncomfortable. In many cases, the issue is not the light source itself, but how the glass diffuses light.

In this guide, we explain:

What light diffusion really means

How clear, frosted, and opal glass differ technically

How each glass type affects glare, brightness, and ambiance

Which applications each option is best suited for

How professional manufacturers optimize diffusion through glass design

This article is written for B2B decision-makers who need both engineering clarity and commercial confidence.

Light diffusion refers to how evenly light is scattered as it passes through glass.

Instead of allowing light rays to travel straight through (which causes glare and hot spots), diffused glass:

Scatters light in multiple directions

Softens brightness

Reduces visual discomfort

In lamp shades, proper diffusion is essential to:

Eliminate harsh glare

Create a comfortable lighting environment

Enhance perceived quality of the fixture

Poor diffusion is one of the main reasons lighting products receive negative feedback—even when using high-quality LEDs.

Modern LED technology is highly efficient, but also:

Extremely directional

Very bright at the source

Without proper diffusion:

The LED chip becomes visible

The light appears uneven

The fixture feels cheap or uncomfortable

This is why glass selection is as important as LED selection in professional lighting design.

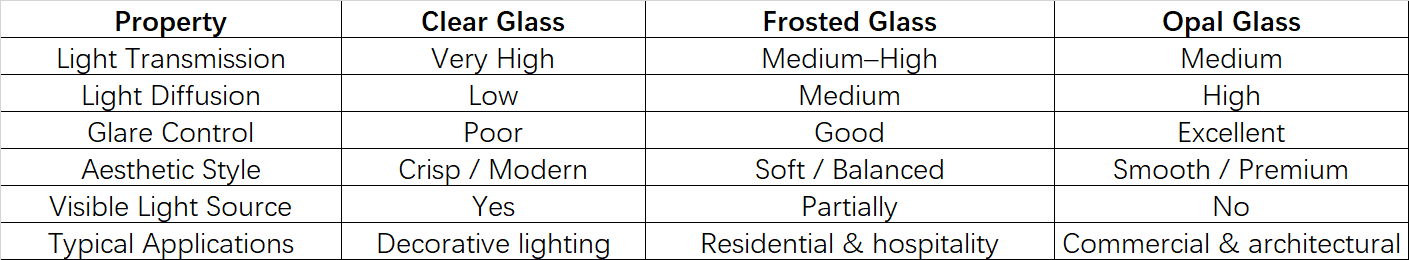

Before diving deeper, here is a high-level comparison:

Each option has its place—but using the wrong one can compromise the entire lighting experience.

Clear glass is transparent glass with minimal surface treatment. It allows light to pass through with very little scattering.

High light transmission

Minimal diffusion

High contrast between light source and surroundings

This means:

The bulb or LED is clearly visible

Light intensity appears high

Glare is common

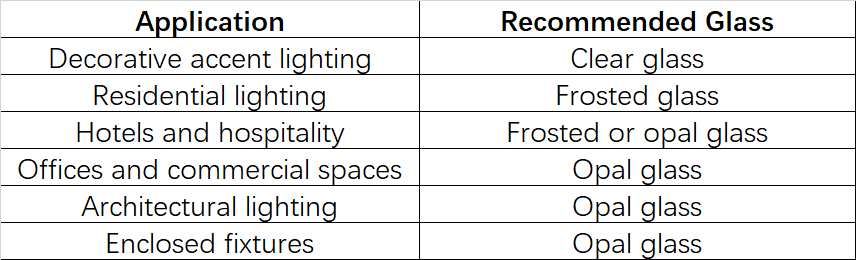

Clear glass is often chosen for:

Decorative lighting

Vintage or industrial-style lamps

Statement fixtures where the bulb is part of the design

It works well when:

Filament-style bulbs are used

Visual brightness is desired

The fixture is not in direct line of sight

In functional or commercial lighting, clear glass can cause:

Harsh glare

Eye discomfort

Uneven illumination

For hospitality and public spaces, clear glass often fails visual comfort requirements unless combined with:

Low-luminance bulbs

Internal diffusers

Secondary optical elements

Frosted glass is created by:

Acid etching

Sandblasting

Surface frosting treatments

These processes roughen the glass surface, causing light to scatter.

Good balance between transmission and diffusion

Softened light output

Reduced visibility of the light source

Frosted glass diffuses light without dramatically reducing brightness.

Frosted glass is widely used because it:

Reduces glare effectively

Maintains sufficient brightness

Works with a wide range of light sources

Common applications include:

Residential lighting

Hotel rooms and corridors

Wall sconces and pendant lights

For many lighting manufacturers, frosted glass is the default choice due to its versatility.

The diffusion effect of frosted glass depends on:

Frosting depth

Surface uniformity

Glass thickness

Inconsistent frosting can lead to:

Patchy light distribution

Visible streaks or spots

Professional manufacturers control frosting processes carefully to ensure consistent optical performance across batches.

Opal glass is a type of glass with diffusing material integrated into the glass body, not just applied to the surface.

Unlike frosted glass:

Diffusion comes from within the glass

Light is scattered more evenly

High diffusion

Soft, uniform light output

Light source completely hidden

Opal glass creates a smooth, glowing appearance that is widely perceived as high-end and professional.

Opal glass is preferred for:

Commercial lighting

Hospitality and public spaces

Architectural and office environments

Its benefits include:

Excellent glare control

Visual comfort compliance

Consistent appearance from all angles

For brands, opal glass:

Enhances perceived product quality

Reduces complaints related to glare

Supports premium positioning

Compared to clear or frosted glass, opal glass:

Has lower light transmission

Requires slightly higher lumen output

Is more complex to manufacture

However, in professional environments, the benefits often outweigh the added cost.

Glass type alone does not determine diffusion quality. Thickness plays a major role.

Thicker glass increases diffusion

Thinner glass allows more direct transmission

For example:

Thin frosted glass may still reveal LED hot spots

Thicker opal glass produces a uniform glow

Professional manufacturers optimize:

Thickness

Glass composition

Surface treatment

to achieve the desired lighting effect.

Cause: Clear or thin frosted glass with directional LEDs

Cause: Inconsistent frosting or thickness variation

Cause: Overly thick or low-transmission opal glass

Cause: Poor-quality diffusing materials or coatings

Understanding these issues helps buyers specify the right solution upfront.

Achieving consistent diffusion is not accidental. It requires:

Controlled glass composition

Precise surface treatment

Strict thickness tolerance

Optical inspection and testing

A professional glass lamp shade manufacturer should provide:

Light diffusion samples

Application-based recommendations

Batch consistency assurance

This technical support significantly reduces design risk for B2B buyers.

Before committing to production, professional buyers should:

Test samples with actual light sources

Evaluate glare from different angles

Review light uniformity in real environments

Digital simulations alone are not enough—physical testing is essential.

Not always. Opal glass offers superior diffusion, but frosted glass may be sufficient for residential or decorative use.

Yes, if combined with low-glare bulbs or internal diffusers.

It reduces glare more than brightness, making it a good balance in many applications.

Yes, through thickness, surface treatment, and internal coatings.

Our process ensures quality before mass production

Design confirmation with customer

In-house mold development at our facility

Sample production for approval

Customer testing and feedback

Mass production only after final sample approval

We offer comprehensive custom packaging for safe international shipping:

We operate multiple production lines with experienced workers, enabling stable mass production for orders of all sizes. Our facility ensures consistent quality and reliable on-time delivery for both small batches and large-volume orders.

Lead times vary by complexity and quantity:

We export to over 150 countries and regions worldwide, including:

We maintain a comprehensive global distribution network.

Light diffusion is not a minor detail—it defines how a lighting product is experienced.

Clear glass emphasizes brightness and design

Frosted glass balances comfort and efficiency

Opal glass delivers premium visual performance

For B2B lighting projects, choosing the right glass diffusion solution reduces risk, improves user comfort, and strengthens brand reputation.

Working with a manufacturer that understands optics, materials, and real-world applications ensures your lighting products perform exactly as intended.