Heat-Resistant Industrial & Designer Lighting | Thermal Shock ΔT150°C

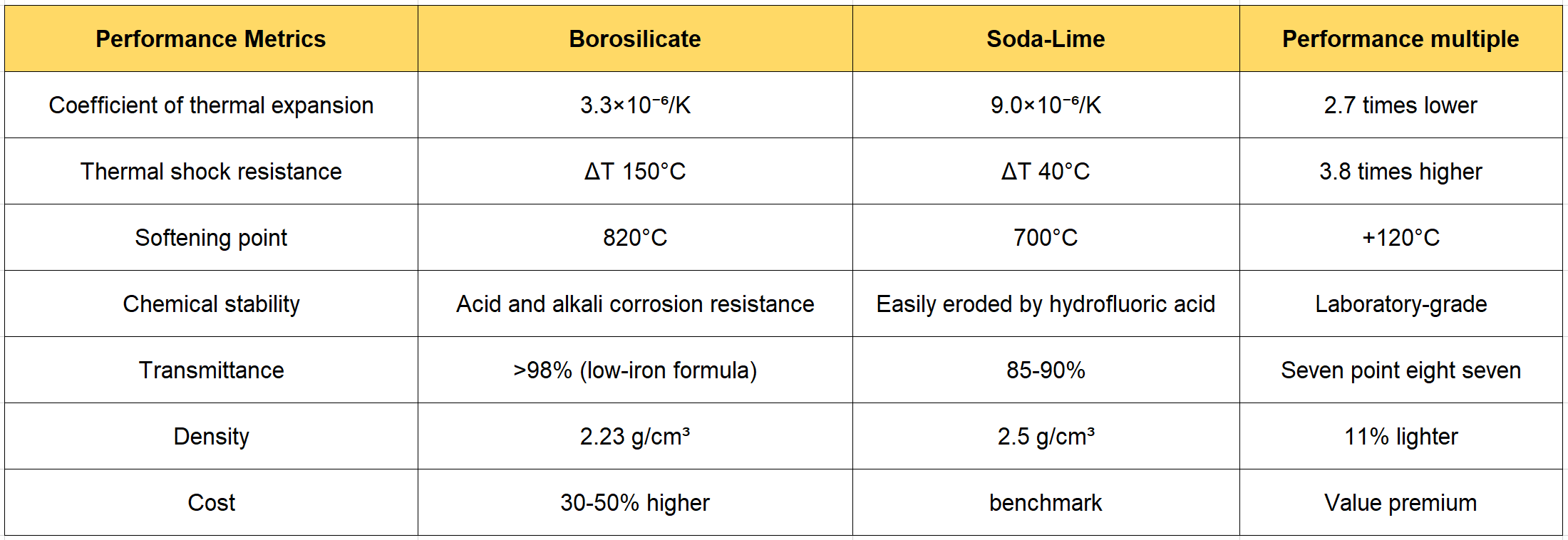

Precision lampwork borosilicate glass shade manufacturer. Thermal shock resistant -20°C to 300°C, 3.3×10⁻⁶/K expansion coefficient. Custom scientific-grade clarity for industrial, lab & outdoor lighting.

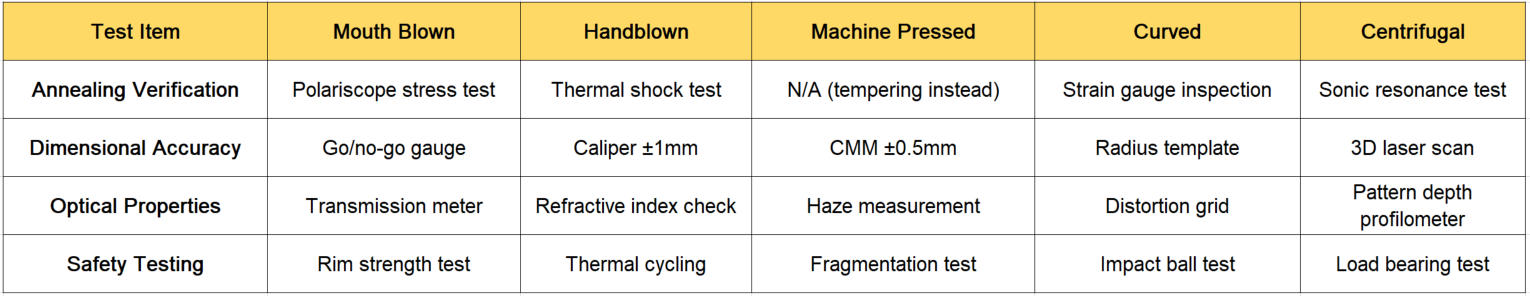

Lampwork process description: Different from large-scale blowing, lampwork uses a precision gas-oxygen torch (with temperature precisely controlled to ±20°C) for manual shaping, suitable for small batches (50-2000 pieces), high precision (±0.5mm), and complex structures (internal channels, multi-layer nesting) of borosilicate glass molding.

Sphere, Cylinder, Dome, Conical, Flared

Φ30mm – Φ300mm (standard), Φ400mm+ (segmented welding)

1.5mm (Lightweight) – 8mm (Explosion-proof)

Standard screw, flange edge, ground seal, custom buckle

Fire polishing (optical grade), frosted diffusion, striped anti-slip, internal prism

Ultra-white transparency, light blue (standard), amber filter, customized dichroic

Vacuum jacket (thermal insulation), internal threads, embedded grounding metal ring, observation window flange

When your lighting faces thermal cycling, chemical exposure, or impact risk, soda-lime glass fails. Our lampwork borosilicate combines scientific-grade thermal stability with artisan precision for specifications where failure is not an option.

More samples of Lampwork Borosilicate Glass Lamp Shades

Borosilicate glass (SiO₂ 80.6%, B₂O₃ 13.0%, Al₂O₃ 2.3%) owes its thermal shock resistance to low thermal expansion. When heated, it expands 2.7× less than soda-lime, minimizing stress at material interfaces—critical for sealed fixtures and rapid temperature changes.

6 steps to cooperation

Lampwork uses precision bench-mounted torches for small-batch (50-2000pcs), high-complexity pieces with internal features. Regular blowing is for high-volume simple shapes. Lampwork allows ±0.3mm tolerance vs ±1.0mm for blown, and enables structures like cooling channels impossible in molds.

Yes. Our standard 2-3mm wall handles 150°C continuous surface temp (100W halogen equivalent). For 300W+ industrial halogen, specify 5-6mm wall or our ceramic-coated IR-reflective option, reducing surface temp by 40°C.

Request our “Outdoor Extreme” specification: (1) Wall thickness ≥3mm for impact, (2) Fire-polished surfaces only (no grinding stress concentrators), (3) Optional hydrophobic nano-coating for ice/snow shedding, (4) Thermal cycling test report included.

Ventilation helps but doesn’t eliminate thermal shock from rain on hot fixtures, or cold-start heating. For mission-critical or hard-to-reach installations, borosilicate’s 3.8× thermal shock margin provides insurance against unpredictable conditions.

Yes. We specialize in glass-to-metal seals: Kovar alloy rings for vacuum systems, stainless steel flanges for industrial mounting, or embedded threads. CTE-matched materials prevent seal failure during thermal cycling.

The 48-hour annealing is our secret weapon. While others rush 12-hour cycles, we eliminate 99.9% residual stress. Result: your shades won’t crack in Dubai’s heat or Oslo’s freeze, years later.

Sandblasting/acid etching/hand painting/electroplating (optional)

From raw glass selection to precision finishing, we control every step to deliver consistent and high-quality glass lamp shades.

·Professional glass lamp shade manufacturer with full production capabilities

·In-house furnace, molding, annealing and finishing lines

·Suitable for OEM, ODM and project-based glass lamp shade solutions

Our fully integrated glass lamp shade manufacturing process allows us to deliver stable quality, flexible customization, and reliable lead times for global customers.

A small river named Duden flows by their place and supplies it with the necessary regelialia. It is a paradise

We have been working with Jingxin Glassware for several years, and they have proven to be a very reliable glass lamp shade manufacturer. Their ability to understand our design ideas and turn them into consistent, high-quality products is impressive. From sampling to mass production, communication is always clear and professional. Most importantly, the product quality remains stable across different orders.

Jingxin supported us on multiple hotel lighting projects, supplying customized glass lamp shades for guest rooms and public areas. The products met our expectations in terms of appearance, light diffusion, and durability. Packaging was secure and suitable for long-distance shipping. Their team is responsive, detail-oriented, and experienced in handling project-based orders. We consider Jingxin a long-term partner for hospitality projects.

As a trading company, consistency and transparency are extremely important to us. Jingxin provides stable quality, clear production schedules, and honest communication throughout the process. They are flexible with customization, MOQ, and packaging, which helps us better serve our customers. Thanks to their reliable delivery and professional support, we have successfully expanded our glass lamp shade business in multiple markets.