Custom Studio Lighting | Mouth Blown & Lampwork | OEM/ODM

Handmade glass lamp shade manufacturer combining traditional mouth blowing and precision lampwork. Custom silhouettes, layered colors, and textured finishes. 50pc artisan batch MOQ. DFM engineering support.

Controlled Variability: We define a “variability bandwidth” for each design – for example, a gradual change in wall thickness from 2-4mm is acceptable, and a diameter variation of ±8mm is acceptable. Within this range, the artisan has the freedom to create, ensuring family similarity in mass-produced products.

Globe sphere, Organic, Asymmetric, Sculptural sculpture

Φ80-350mm (blowing), Φ30-200mm (lamp worker)

1.5-8mm, Variable or uniform

Solid color, Layered layering, Gradient gradient, Reactive reactive color

Solid solid color, Layered layering, Gradient gradient, Reactive reactive color Smooth, Dimple concave points, Ribbed stripes, Crackle broken patterns, Reticulated mesh

Fire polished, Tooled thread, Applied coupling, Flared horn

Internal cavity, Encased inlay, Applied decoration, heat sealed decoration

Our team is skilled at creating visually striking and cohesive kits that make your club instantly recognizable, both on and off the field.

Handmade doesn’t mean uncontrolled. Our artisans execute engineered designs with human sensitivity — capturing variations that machines cannot replicate while maintaining specification-grade functionality.

More samples of Handmade Glass Lamp Shade

6 steps to cooperation

“Controlled variability” system: we define acceptable variation bands for each design (e.g., diameter ±8%, wall thickness ±30%). Artisans work within these engineering limits, ensuring family resemblance while preserving human character. Each batch is sampled and measured.

Our handmade serves specification lighting — engineered for installation compatibility, thermal safety, and batch consistency. Pure studio art prioritizes expression over function. We bridge both: craft soul with engineering discipline.

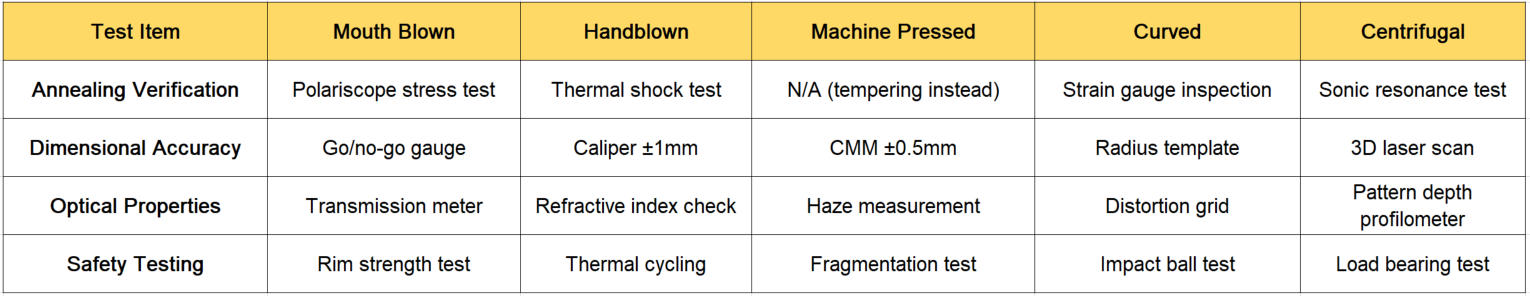

Yes. We control material composition (lead-free, thermal expansion), annealing cycles (stress elimination), and offer post-forming tempering. Components are tested and certified; the handmade element is the forming process, not safety compromise.

Three constraints: (1) Size limited by human arm reach and cooling speed (max Φ350mm), (2) Tolerance ±1-2mm vs ±0.3mm machined, (3) Daily output 20-50 pieces vs 1,000+ automated. Benefits: unlimited form complexity, surface texture, and color layering without mold costs.

6-month apprenticeship mastering specific designs, followed by continuous calibration against master samples. Batch sampling and customer feedback loop into training updates. Each piece is traceable to individual artisan.

Within our artisan batch system, yes — we can dedicate a production run to your exclusive design with custom variation bands. For true one-offs, we partner with associated studio artists (separate commission process).

Step 4-6 is where human resides. The artisan reads glass viscosity through hand feedback (thermal conductivity, surface tension), making micro-decisions every 3-5 seconds that no sensor can replicate.

Stable temperature of 1200 ° C material pool

Air pressure 0.1-0.3MPa, mold/free blowing

Stacking, wrapping, or powder coating

Tool temperature, pressure, timing

Graphite tool shaping

560 ° C, 24-48 hour program

Cutting, drilling, fire polishing, surface faceting/sandblasting/silver plating

From raw glass selection to precision finishing, we control every step to deliver consistent and high-quality glass lamp shades.

·Professional glass lamp shade manufacturer with full production capabilities

·In-house furnace, molding, annealing and finishing lines

·Suitable for OEM, ODM and project-based glass lamp shade solutions

Our fully integrated glass lamp shade manufacturing process allows us to deliver stable quality, flexible customization, and reliable lead times for global customers.

Customer feedback is our confidence and belief that we are getting better and better

We have been working with Jingxin Glassware for several years, and they have proven to be a very reliable glass lamp shade manufacturer. Their ability to understand our design ideas and turn them into consistent, high-quality products is impressive. From sampling to mass production, communication is always clear and professional. Most importantly, the product quality remains stable across different orders.

Jingxin supported us on multiple hotel lighting projects, supplying customized glass lamp shades for guest rooms and public areas. The products met our expectations in terms of appearance, light diffusion, and durability. Packaging was secure and suitable for long-distance shipping. Their team is responsive, detail-oriented, and experienced in handling project-based orders. We consider Jingxin a long-term partner for hospitality projects.

As a trading company, consistency and transparency are extremely important to us. Jingxin provides stable quality, clear production schedules, and honest communication throughout the process. They are flexible with customization, MOQ, and packaging, which helps us better serve our customers. Thanks to their reliable delivery and professional support, we have successfully expanded our glass lamp shade business in multiple markets.