Heavy Cast Decorative Lighting | 3D Relief Patterns | Luxury Hospitality OEM

Premium centrifugal cast glass lamp shade manufacturer. 1050°C molten pour, 800-1200 RPM precision casting. Deep 3D relief, jewel-tone colors, 2-8kg heirloom quality. Custom molds for luxury hotels & heritage restoration.

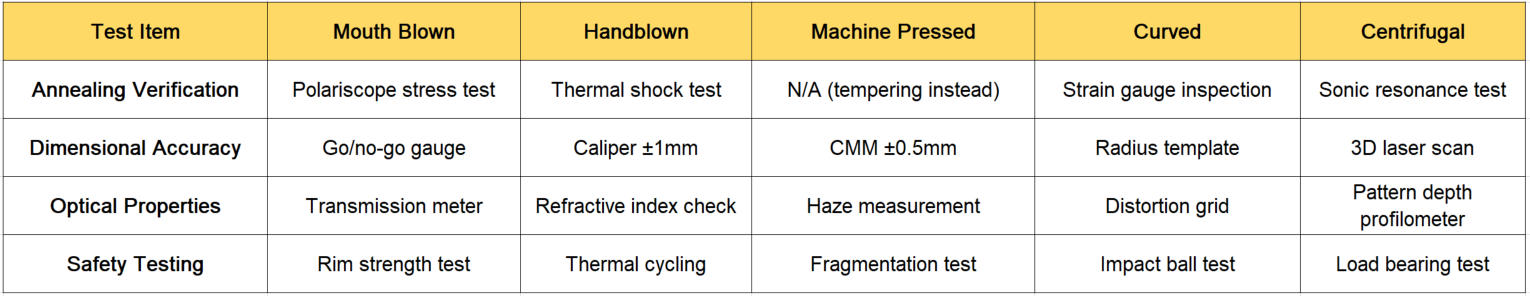

Mold Engineering: Complex 3D reliefs are carved using CNC-engraved aluminum molds or hand-carved cast iron molds, with surfaces plated with chromium to extend the lifespan to over 2000 cycles. Before each mold is used, a boron nitride release agent is applied to ensure complete transfer of the pattern.

Bell, Urn, Globe, Flower, Custom sculptural

Φ80mm – Φ400mm (standard), Φ600mm+ (segmented combination)

60mm – 350mm, with an aspect ratio of up to 1:1

3D flowers, geometric cuts, vine scrolls, Art Deco lines, customized logos/badges

Amber, Ruby, Cobalt, Emerald, Amethyst, Gradient Bicolor

Fire polishing for high gloss, local frosting contrast, hand-cutting facets, gold/silver foil lining

Embedded copper screw insert, stainless steel flange, concealed lifting structure, internal LED module bracket

Our team is skilled at creating visually striking and cohesive kits that make your club instantly recognizable, both on and off the field.

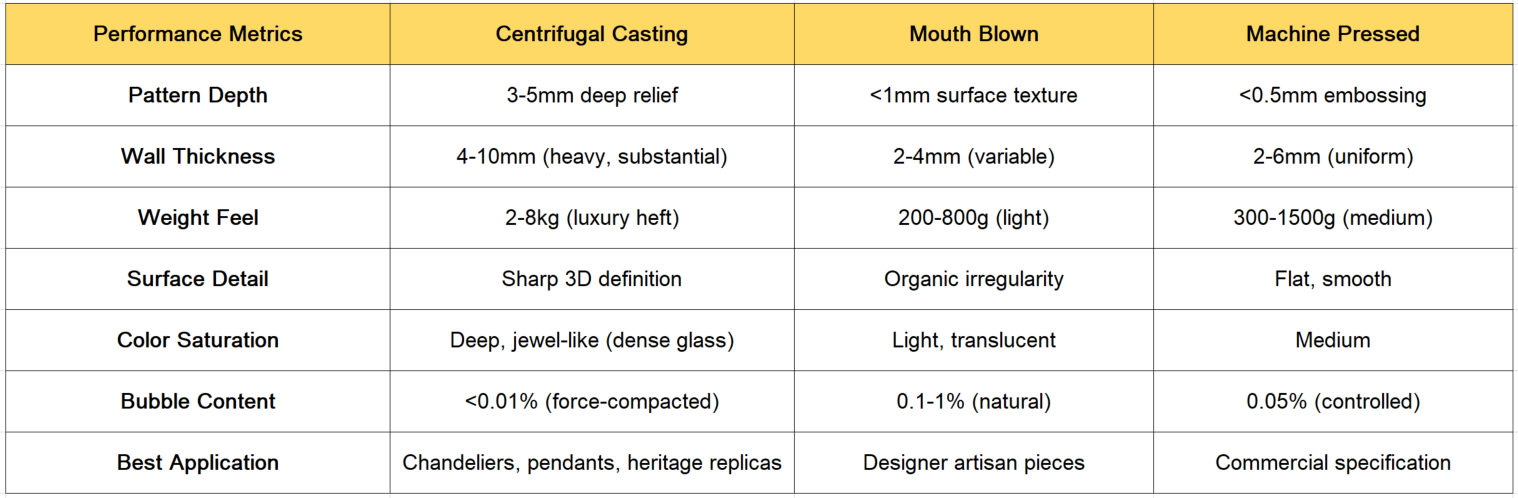

Centrifugal force doesn’t just shape glass — it compacts it. Molecular density increases, bubbles vanish, and patterns emerge with jewel-like depth impossible in blown or pressed methods. This is gravity-defying mass, frozen in light.

More samples of Centrifugal Glass Lamp Shade

Centrifugal casting exploits rotational force (F=mω²r) to drive molten glass into mold cavities at 5-10× atmospheric pressure. This force compaction eliminates bubbles, captures micro-detail, and creates radial symmetry perfect for floral, geometric, and figurative relief patterns.

6 steps to cooperation

Three factors: (1) Mold cost $5,000-15,000 vs $500-3,000 for other methods, (2) Cycle time 10-15 minutes vs 30-45 seconds for pressing, (3) Material usage 2-8kg vs 0.2-1kg. However, for patterns >2mm depth or weights >1kg, centrifugal is the only viable method. Amortized over 500+ units, per-piece cost becomes competitive.

Standard 3-5mm depth for clear definition. Maximum 8mm possible but increases wall thickness to 10mm+ and weight proportionally. Deep undercuts (>90°) require multi-part molds and show seam lines.

Yes, but thermal management critical. Dense glass (4-10mm) insulates well — LED heat must dissipate through fixture housing, not shade. We design integrated heat sinks or specify low-heat COB modules. Surface temp must stay <80°C for annealed glass.

We maintain a library of 200+ historical color formulations. For unique matches, we perform spectrophotometry on original samples and custom-batch glass. Success rate 95%+ for colors; mercury glass effects require artistic hand-spraying for authentic variation.

Practical limit Φ400mm/8kg for handling safety. Larger designs use segmented construction — multiple cast sections joined with hidden metal hardware or UV-cured optical adhesive. Record: Φ1.2m chandelier assembled from 8 cast petals.

Glass hardness 5.5 Mohs — patterns are permanent and wear-resistant. However, deep relief can collect dust; we recommend annual compressed air cleaning. For high-touch areas (table lamps), specify smooth surfaces or shallow texture.

The 72-hour annealing is non-negotiable. Centrifugal force compacts glass at molecular level — without stress relief, these dense shades would self-destruct months later. We wait so your grandchildren inherit functional art.

CNC aluminum mold or handmade cast iron mold, with chrome plating on the surface and boron nitride spraying

The tank furnace is at 1550°C, with the colorant homogenized, and the material is discharged at 1050°C

Inject a fixed amount of molten glass (2-8kg) into the center of the rotating mold

Spin at 800-1200 RPM for 30-90 seconds to compact the glass using centrifugal force

Slow down the rotation and cool it down to 600°C with air cooling, then open the mold

Maintain at 560°C for 72 hours to eliminate stress

Cutting, drilling, fire polishing, surface faceting/sandblasting/silver plating

From raw glass selection to precision finishing, we control every step to deliver consistent and high-quality glass lamp shades.

·Professional glass lamp shade manufacturer with full production capabilities

·In-house furnace, molding, annealing and finishing lines

·Suitable for OEM, ODM and project-based glass lamp shade solutions

Our fully integrated glass lamp shade manufacturing process allows us to deliver stable quality, flexible customization, and reliable lead times for global customers.

Customer feedback is our confidence and belief that we are getting better and better

We have been working with Jingxin Glassware for several years, and they have proven to be a very reliable glass lamp shade manufacturer. Their ability to understand our design ideas and turn them into consistent, high-quality products is impressive. From sampling to mass production, communication is always clear and professional. Most importantly, the product quality remains stable across different orders.

Jingxin supported us on multiple hotel lighting projects, supplying customized glass lamp shades for guest rooms and public areas. The products met our expectations in terms of appearance, light diffusion, and durability. Packaging was secure and suitable for long-distance shipping. Their team is responsive, detail-oriented, and experienced in handling project-based orders. We consider Jingxin a long-term partner for hospitality projects.

As a trading company, consistency and transparency are extremely important to us. Jingxin provides stable quality, clear production schedules, and honest communication throughout the process. They are flexible with customization, MOQ, and packaging, which helps us better serve our customers. Thanks to their reliable delivery and professional support, we have successfully expanded our glass lamp shade business in multiple markets.