Precision Thermoformed Lighting | Shallow Profile Wall & Ceiling Solutions | OEM/ODM

Custom curved glass lamp shade manufacturer. CNC thermal forming 650-720°C, shallow profile 15-40mm depth. Uniform light diffusion for wall sconces, flush mounts & architectural lighting. Fire-polished edges.

Hot bending process control: The temperature gradient in the infrared heating zone is maintained at ±5°C to prevent optical distortion. For large curvature (R<150mm), vacuum suction molding is used to assist in forming, ensuring precision in fitting the mold.

Ceiling lights, wall lights, corridor lights, elevator lighting

Diameter: 100-600mm, Depth: 15-40mm (standard), Maximum: 800mm/60mm

R80mm (tight) to R500mm (gentle), with optional reverse curvature

Clear, Opal, Patterned (Nashiji, Flora, Mayflower), Tempered

Fire-polished round edge (standard), flat-polished, beveled edge, rolled edge

Glossy, Sandblasted, Acid-etched, Diffusion film, Anti-glare UGR<16 to maximum output

Embedded screw holes, buckle slots, magnetic edges, silicone pad sealing slots, and emergency lighting sign embedding slots

Our team is skilled at creating visually striking and cohesive kits that make your club instantly recognizable, both on and off the field.

When ceiling height is precious and clean lines are sacred, curved glass transforms two-dimensional sheets into three-dimensional luminaires. Zero visual weight, maximum luminous impact.

More samples of Curved Glass Lamp Shade

Thermal forming (heat slumping) utilizes CNC-controlled infrared heating zones to soften glass to plastic state (viscosity 10⁷·⁶ poise) at 650-720°C, then gravity-sag or vacuum-form over precision ceramic molds. Controlled cooling preserves optical clarity while locking curvature within ±0.5mm tolerance.

6 steps to cooperation

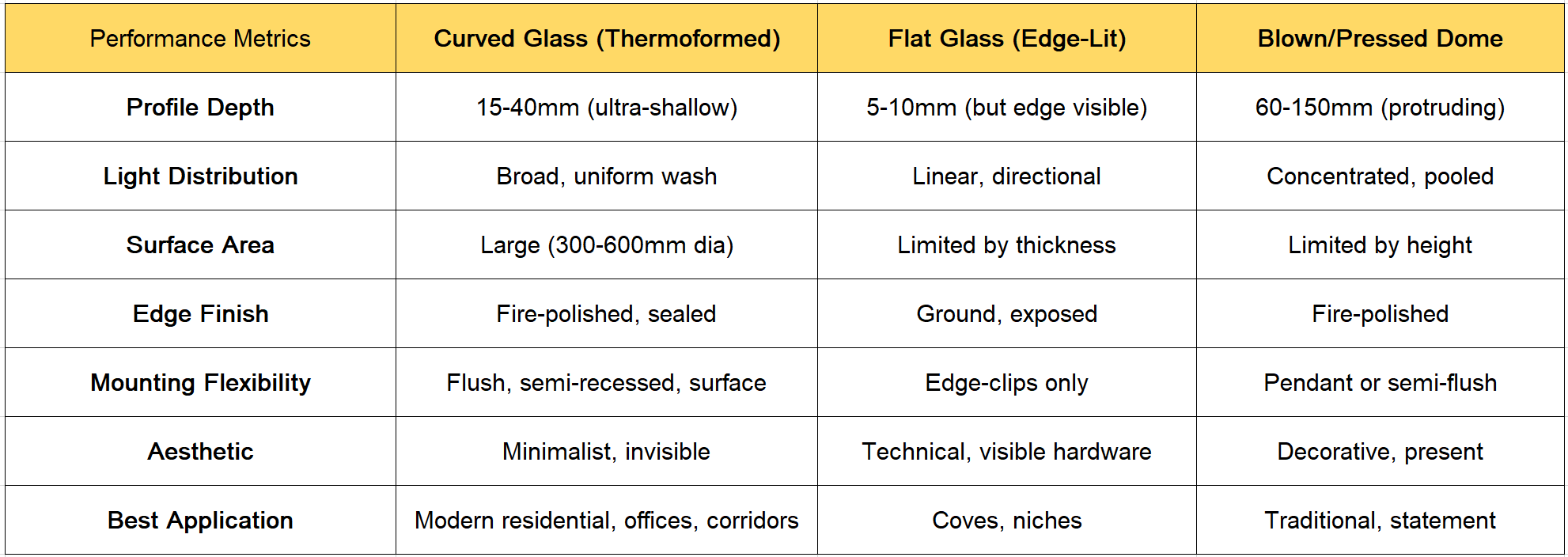

Practical minimum 15mm depth for Φ200mm diameter (R≈300mm). Shallower profiles risk spring-back and optical distortion. For <15mm, consider flat edge-lit panels (different technology, not true curved glass).

Annealed curved glass retains base material strength. For safety-critical applications, we post-temper after forming (curved tempered), achieving 5× strength with maintained curvature (±1mm tolerance relaxation).

Yes. We reverse-engineer ceiling radius from site templates or 3D scans, then CNC machine matching ceramic molds. Tolerance ±2mm over 600mm span. For compound curves (saddle shapes), vacuum forming enables 3D contouring.

Three strategies: (1) Thickness increase to 4-5mm for >Φ400mm, (2) Ribbed or stepped reinforcement on hidden surface, (3) Tempering for structural rigidity. Engineering consultation included for >Φ500mm designs.

Yes with proper edge sealing. Our fire-polished rims with silicone gasket achieve IP44 (splashing water). For IP65 (jets), specify laminated curved glass or additional frame sealing. Not recommended for submersion.

Annealed: 2000×1000mm (limited by kiln size). Tempered: 1200×600mm (quench uniformity limit). Larger areas use butt-jointed multiple pieces with optical-grade UV adhesive (seam nearly invisible when lit).

The magic happens in the thermal gradient — too hot, glass flows and thins; too cold, it resists and springs back. Our CNC zone control maintains the 50°C sweet spot across 600mm spans, achieving curvature accuracy impossible in manual kilns.

From raw glass selection to precision finishing, we control every step to deliver consistent and high-quality glass lamp shades.

·Professional glass lamp shade manufacturer with full production capabilities

·In-house furnace, molding, annealing and finishing lines

·Suitable for OEM, ODM and project-based glass lamp shade solutions

Our fully integrated glass lamp shade manufacturing process allows us to deliver stable quality, flexible customization, and reliable lead times for global customers.

Customer feedback is our confidence and belief that we are getting better and better

We have been working with Jingxin Glassware for several years, and they have proven to be a very reliable glass lamp shade manufacturer. Their ability to understand our design ideas and turn them into consistent, high-quality products is impressive. From sampling to mass production, communication is always clear and professional. Most importantly, the product quality remains stable across different orders.

Jingxin supported us on multiple hotel lighting projects, supplying customized glass lamp shades for guest rooms and public areas. The products met our expectations in terms of appearance, light diffusion, and durability. Packaging was secure and suitable for long-distance shipping. Their team is responsive, detail-oriented, and experienced in handling project-based orders. We consider Jingxin a long-term partner for hospitality projects.

As a trading company, consistency and transparency are extremely important to us. Jingxin provides stable quality, clear production schedules, and honest communication throughout the process. They are flexible with customization, MOQ, and packaging, which helps us better serve our customers. Thanks to their reliable delivery and professional support, we have successfully expanded our glass lamp shade business in multiple markets.