Heat-Resistant Industrial & Designer Lighting | Thermal Shock ΔT150°C

Industrial machine pressed glass lamp shade factory. Automated pressing delivers ±0.3mm dimensional repeatability across 10,000+ units. Tempered, alabaster & opal finishes. Hospitality & retail lighting solutions.

Technical note box: Complex shapes are achieved through the use of multi-part molds (3-6 part molds) with zero draft angle design, coupled with automatic demolding robots, ensuring the intact removal of thin-walled deep-cavity products.

Dome, Dish, Cylinder, Cone, Pyramid, Custom CAD

Φ60mm – Φ400mm (standard), Φ600mm+ (extra-large mold)

20mm – 250mm, with a deep cavity ratio up to 1:1.5

2.0mm (Lightweight) – 6.0mm (Explosion-proof)

E27/E26 precision screw base, E14/E12, GU10 adapter ring, snap-on type, no burr on the base

High-gloss fire polishing, matte sandblasting, acid etching satin, prism pattern, honeycomb diffusion, customized leather pattern

Ultra-white transparent, milky white (30-70% light transmittance), amber, smoke gray, custom powder color

Tempered (5× strength), semi-tempered, wired explosion-proof, film-covered splash-proof

Machine pressing utilizes H13 tool steel molds (Rockwell hardness 48-52 HRC) with automated glass gob weight control (±2%), pressing force 0.5-2.5MPa, and precision timing (15-45 second cycle) to achieve injection-molding-level repeatability in glass.

Machine pressing utilizes H13 tool steel molds (Rockwell hardness 48-52 HRC) with automated glass gob weight control (±2%), pressing force 0.5-2.5MPa, and precision timing (15-45 second cycle) to achieve injection-molding-level repeatability in glass.

6 steps to cooperation

Standard MOQ 500pcs per design. Lead time 3-4 weeks including mold making (7-10 days for new designs). For 5,000+ units, 2-week express production available. Repeat orders: 1-2 weeks.

Three controls: (1) All glass from single furnace batch for orders <10,000pcs, (2) Inline spectrophotometer monitoring with automatic furnace chemistry adjustment, (3) Sample retention comparison for multi-batch large orders. Guaranteed ΔE<1.0.

Yes, our DFM team optimizes designs for pressing: adding draft angles (minimum 1°), uniforming wall thickness, simplifying undercuts. 90% of blown silhouettes can be adapted while maintaining 95% visual similarity at 40% lower cost.

Tempered (our standard): Surface compression >69MPa, breaks to small granules, 5-7× strength, 250°C max. Heat-strengthened: Surface compression 24-52MPa, breaks to larger pieces (not safety), 2× strength, 200°C max. We recommend tempered for all overhead/safety applications.

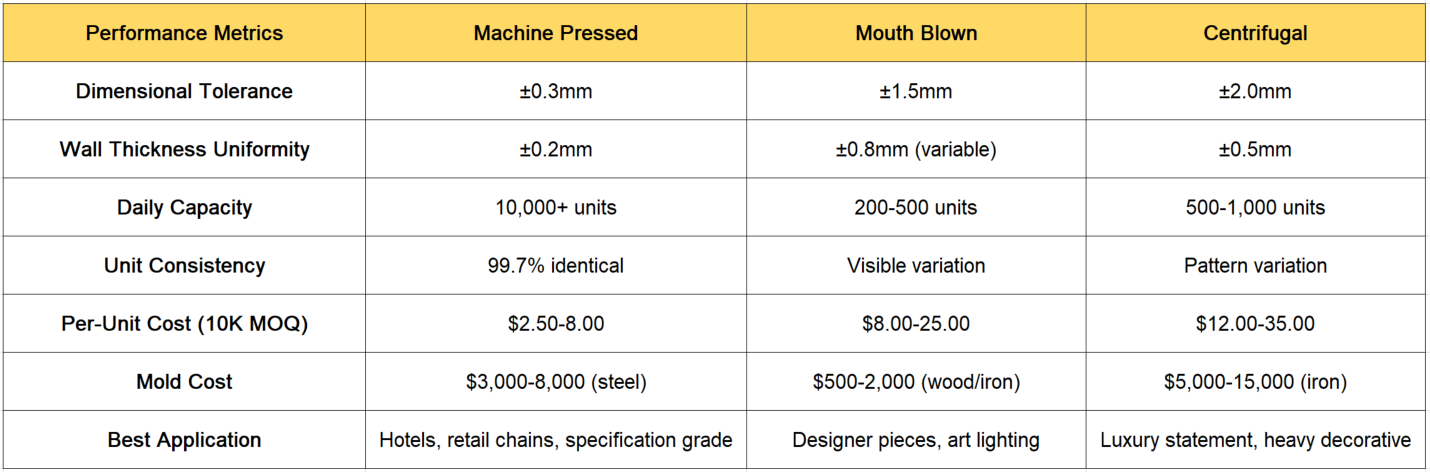

Mold cost $3,000-8,000 amortized over first order or paid upfront. Client-owned molds stored free for 2 years; exclusivity contract available preventing production for competitors. Mold modifications (size variants) at 30% of original cost.

Yes. Standard pressed glass handles 120°C continuous (adequate for LED). For high-lumen density COB arrays, specify our low-iron borosilicate-pressed option (300°C rating, +15% cost) or integrated heat sink interfaces.

Our pressing lines run 24/7 with 99.7% OEE (Overall Equipment Effectiveness). Every shade is laser-marked with batch code, linking to complete production data — furnace temperature, mold ID, operator, inspection results — for full traceability.

From raw glass selection to precision finishing, we control every step to deliver consistent and high-quality glass lamp shades.

·Professional glass lamp shade manufacturer with full production capabilities

·In-house furnace, molding, annealing and finishing lines

·Suitable for OEM, ODM and project-based glass lamp shade solutions

Our fully integrated glass lamp shade manufacturing process allows us to deliver stable quality, flexible customization, and reliable lead times for global customers.

Customer feedback is our confidence and belief that we are getting better and better

We have been working with Jingxin Glassware for several years, and they have proven to be a very reliable glass lamp shade manufacturer. Their ability to understand our design ideas and turn them into consistent, high-quality products is impressive. From sampling to mass production, communication is always clear and professional. Most importantly, the product quality remains stable across different orders.

Jingxin supported us on multiple hotel lighting projects, supplying customized glass lamp shades for guest rooms and public areas. The products met our expectations in terms of appearance, light diffusion, and durability. Packaging was secure and suitable for long-distance shipping. Their team is responsive, detail-oriented, and experienced in handling project-based orders. We consider Jingxin a long-term partner for hospitality projects.

As a trading company, consistency and transparency are extremely important to us. Jingxin provides stable quality, clear production schedules, and honest communication throughout the process. They are flexible with customization, MOQ, and packaging, which helps us better serve our customers. Thanks to their reliable delivery and professional support, we have successfully expanded our glass lamp shade business in multiple markets.