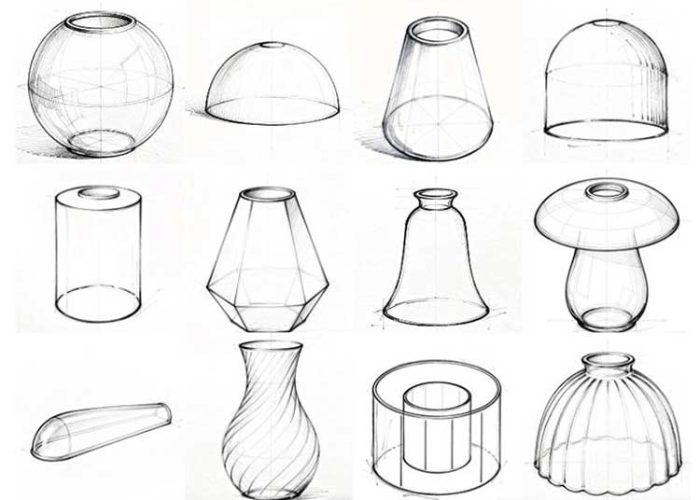

Glass Lamp Shades | Custom Lighting Glassware

Explore our complete glass lamp shade production workflow: batch mixing, mold forming, fire polishing, precision annealing, CNC drilling & surface finishing. ISO-certified process control.

Our 8-stage glass lamp shade production protocol transforms raw silica into specification-grade lighting components through controlled thermal processing (1200°C→560°C), precision mechanical finishing (±0.1mm tolerance), and multi-layer surface engineering. Each phase integrates inline QC checkpoints ensuring thermal shock resistance and structural integrity for commercial lighting applications.

“Your shade color won’t fade or shift between production batches—our spectrophotometry calibration ensures ΔE <1.0 color consistency across 50,000 units.”

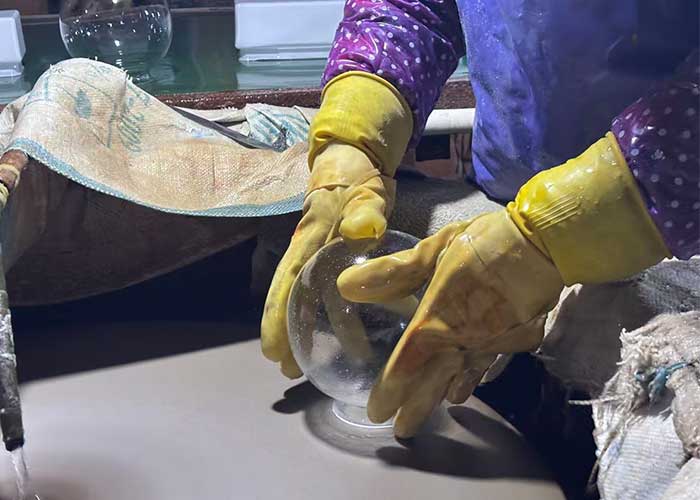

Mold surfaces are coated with boron nitride (BN) spray to prevent glass adhesion and extend mold life to 50,000+ cycles. For opal glass, we control the fluorine atmosphere to create uniform crystalline opacity without streaking.

Process Specification: Raw-cut rims pass through oxy-hydrogen flame jets (1100°C) that melt and resurface the glass edge. This “fire polishing” heals micro-cracks caused by cutting, creating a smooth, rounded profile (R-radius 0.2-0.5mm).Quality Impact: Unpolished rims contain Griffith flaws that propagate under thermal cycling. Our fire-polished rims withstand ΔT >120°C thermal shock without failure.“No more cut fingers during installation, no leaky seals in humid environments—our fire-polished rims meet IP44 ingress protection standards without additional gaskets.”

Cutting:Diamond-embedded copper blades with continuous water cooling prevent thermal shock during trimming. CNC 5-axis positioning ensures ±0.1mm concentricity for asymmetrical designs.

Critical Control Points:

Core Drill Technology: Hollow diamond drills with vacuum chip extraction prevent edge breakout (chipping <0.05mm). Capable of micro-holes Φ3mm in 3mm thick glass without cracking.Countersinking: Automated 90° countersinking for flush-mount screw heads, depth tolerance ±0.1mm.Value:“Custom fixture integration made easy—send us your lamp base CAD files, we’ll match hole patterns, thread sizes, and mounting depths to 0.1mm precision.”

Process Options:

All chamfers polished to 600-grit or higher, eliminating stress concentrators that initiate cracks under mechanical load.

5-Gate Quality Control in Glass Lamp Shade Production

Fire polishing uses 1100°C oxy-hydrogen flames to melt and resurface cut edges, healing micro-cracks and creating a smooth, sealed surface (Ra <0.4μm). Mechanical grinding only removes material but leaves subsurface damage. Fire-polished rims withstand thermal cycling 3× better than ground rims and provide IP44 sealing without gaskets.

We use hollow diamond core drills with vacuum-assisted chip removal and continuous water cooling. This prevents thermal shock (localized heating >200°C) and mechanical stress concentration. Our CNC programming includes “peck drilling” cycles—intermittent retraction to clear debris—reducing breakout to <0.05mm on entry and exit surfaces.

Variation in fluorine evaporation rates during melting causes opal density differences. We control this by: (1) Sealed platinum crucibles preventing volatilization; (2) Spectrophotometric batch testing with ΔE <1.0 tolerance; (3) Climate-controlled storage preventing post-production oxidation.

No. Tempering (thermal or chemical) creates surface compression layers. Post-tempering drilling destroys this balance, causing catastrophic shattering. We drill before tempering, then re-fire-polish holes if tempering is required (rare for shades, common for protective domes).

Sandblasting (mechanical) creates micro-roughness Ra 2-5μm, providing aggressive diffusion but potential cleaning difficulty. Acid etching (chemical) creates sub-micron pore structures, offering softer diffusion and fingerprint resistance. Sandblasting allows gradient patterns; acid etching provides uniform satin finishes.

Our handblown borosilicate (B₂O₃ 13%) withstands thermal shock ΔT = 150°C (e.g., -20°C ice water to +130°C halogen exposure) and continuous service temperatures up to 230°C—ideal for high-wattage industrial lighting where soda-lime glass would fracture.

We operate multiple production lines with experienced workers, enabling stable mass production for orders of all sizes. Our facility ensures consistent quality and reliable on-time delivery for both small batches and large-volume orders.

Lead times vary by complexity and quantity:

We export to over 150 countries and regions worldwide, including:

We maintain a comprehensive global distribution network.